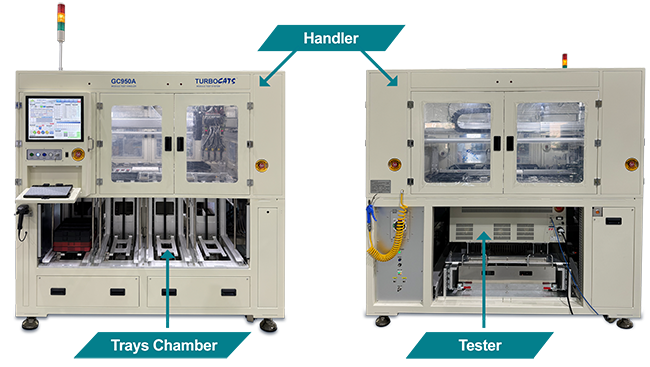

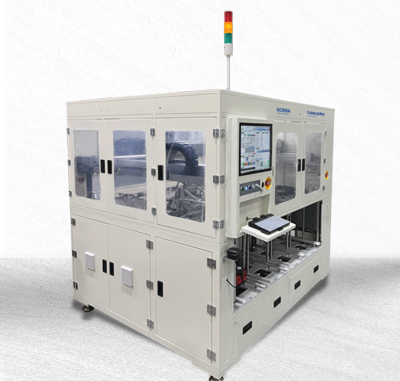

NEW! GC950A Auto Module Handler

DIMM Types: LODIMM /SODIMM

Overview

Solutions Tailored For Large-Volume Production Environment

The GC950A Auto Module Handler is integrated with the TurboCATS memory module tester. It is the automated Pick & Place system which can handle different types of memory modules, including LODIMM /SODIMM. The GC950A handler enables operator-free processing after loading /unloading and offers the module test functionality. The GC950A handler is specifically designed for high-throughput production and reduces human error in your workplace.

Features

All-In-One Convenience

- Supports LODIMM /SODIMM module test functionality

- Operator-free for Loading /Unloading process

- Pass/ Fail Binning

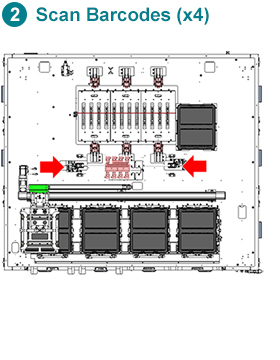

- Read QR code /2D Barcode information of DIMM

- Integrated with TurboCATS memory module tester

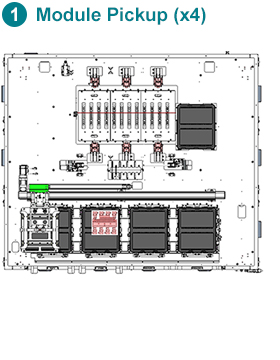

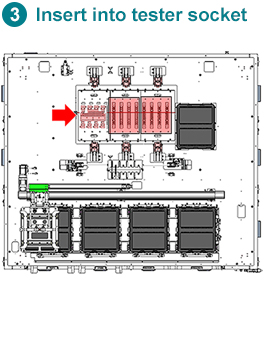

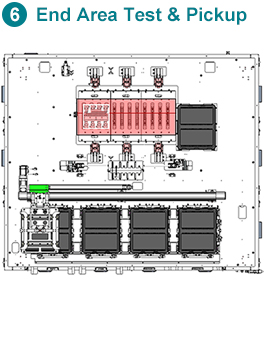

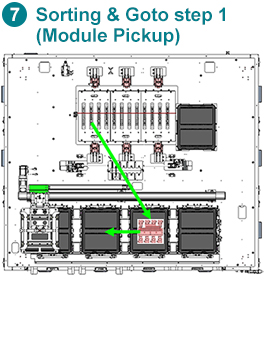

Operations Management Process

Testing Operations Workflow

Ultimate in Plug & Play Handler

GC950A Auto Module Handler

TurboCATS Module Tester

TurboCATS Memory Module Tester

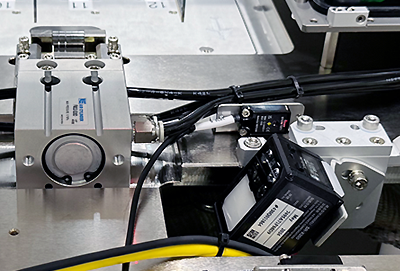

Internal Chamber

QR Code Sensor

Enhanced Features

Maximizing Efficiency in High-Volume Testing

- Provides Barcode or QR Code Read function

- Sends to tester and shows in the log test results

- Allows custom raw trays to be used during the process

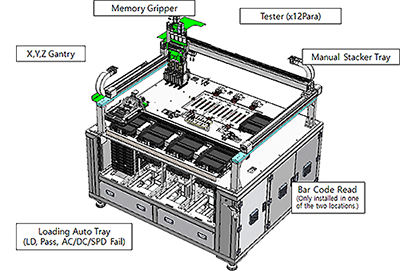

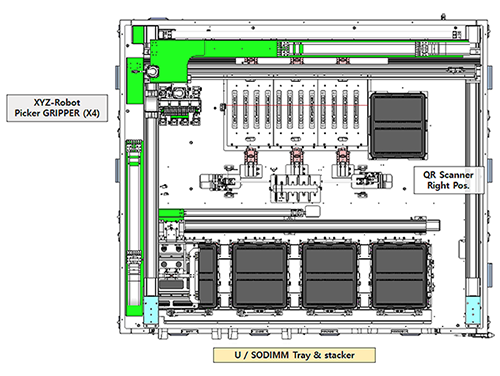

- Module Gripper x 4

- Do not require special C.O.K.

- Pass /Fail Binning (Auto 2BIN, Manual 1BIN)

- - Flexible adjustable gripper

- - Achieves LODIMM /SODIMM auto-pitch

Handler Specifications

| NO | ITEM | SPECIFICATIONS | DESCRIPTION | |||

| 1 | Memory Module | LODIMM /SODIMM | ||||

| 2 | Module carrier | 354.5 * 298.8 * 41.9mm, 10.05 pitch | User supply | |||

| 3 | Auto stackers | 4ea (LD-1ea / EM-1ea / PASS-1ea / NG-1ea) | # of Auto Stacker Module tray (Max. 10 trays) | |||

| 4 | Manual stacker | 1ea (for retest) | IN /OUT by operator | |||

| 5 | Robot gantry | X, Y, Z Axis servo types | Belt and Ball screw | |||

| 6 | Picker (grippers) | Chuck cylinder type (4 grippers) | ||||

| 7 | Tester docking | 1 tester (12Para) | Slide and Cylinder lift /Head guide align pin | |||

| 8 | Tray transfer | Tray body grip for pickup & place | ||||

| 9 | Controller | PC Base and Windows OS | ||||

| 10 | 1D/2D Bar Code Reader | Barcode and Data Matrix Code Reader (SR-X300) | Mounted in base(Move left and right by user) | |||

| 11 | Operation time | Cycle Time (Unload&Sort + Scan&Load) : 60 seconds | Test time zero, All Pass (Reference), Design spec. (will be updated) |

|||

| 12 | Interface | TCP / IP | Default | |||

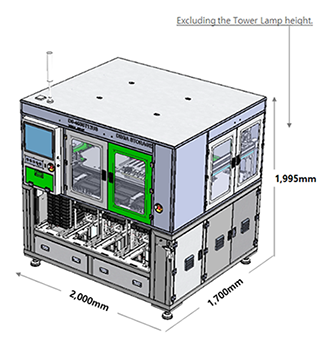

| 13 | Dimensions | 2000 (W) x 1700 (D) x 1995 (H) mm | ||||

| 14 | Utility | 220V (3 phase), 6.5 kw, 30A | ||||

| 15 | Jam Rate | 1 / 1,500 | ||||

| 16 | Air | 0.5MPa | ||||

Mechanical Specifications

Internal Structure of the GC950A

Module Tray Placement (Auto 2BIN, Manual 1BIN)

Dimensions

Note: Information and data are for reference only. Contact our sales team for more details.

Software Screenshot

The GC950A software GUI allows user to build tasks via the drag-and-drop interface.

TURBOCATS, LTD. RESERVES THE RIGHT TO CHANGE PRODUCTS, INFORMATION AND SPECIFICATIONS WITHOUT NOTICE. Products and specifications discussed herein are for reference purposes only. All information discussed herein is provided on an "AS IS" basis, without warranties of any kind.