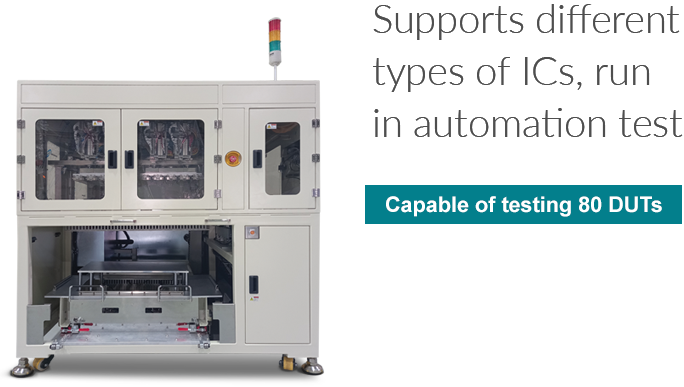

GCOM-6040 IC Handler

A tray pick-and-place type IC handler

Improve Efficiency in High-Volume Manufacturing

Designed to tackle tough tasks

The automated IC test handler GCOM-6040 is an unmatched automated testing solution for different ICs (DRAM, LPDDR and NAND). It can handle up to 80 pieces of ICs in parallel testing, while keeping the integrity of both the tests and DUTs. With the automated IC handler and temperature control settings, the GCOM-6040 can support any testing needs while minimizing potential issues.

The GCOM-6040 handler has an intuitive software GUI - making it easier for engineers to focus on what really matters: the DUTs. The interface can also track multiple testing aspects simultaneously, such as the temperature and the machine settings. With the ability to track multiple tests on one screen, engineers can get better results with less effort at times.

Introducing the Automated IC Handler GCOM-6040

Work together seamlessly

Drag and Drop Operation

Loading & Unloading Robot

- 6 pickers (variable pitch)

- Rubber pad pickup

Shuttle Buffer

- Place 80 each pockets

- Supports load and unloading

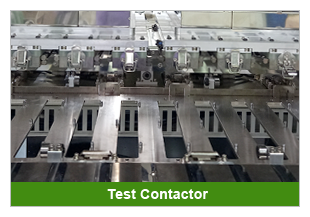

Test Contractor

- One touch clamp (Easy Kit)

- Direct heating

Tray Stacker

- Loader, Empty tray stacker: 30 trays

- Unloading stacker: 4 auto bins

- Manual stacker: 2 manual bins

- Top/ Down open stacker

Mechanical Layout

Reference Cycle-Time

- Load/ Unload picker: 6 pickers (variable pitch)

- Bin: All bin 1

- Tray: 8 x 16 arrays

- Room temperature: 25°C

- Cycle time = loading + sorting + index (7 seconds).

Note: Index time: Shuttle buffer in & Out time

| Cycle Time Summary | Para | Sum | Loading | Sorting | Index |

| 40 para | 79 secs | 36 secs | 36 secs | 7 secs | |

| 60 para | 131 secs | 62 secs | 62 secs | 7 secs | |

| 80 para | 151 secs | 72 secs | 72 secs | 7 secs |

Reference UPH

| Para/ Test Time [sec] | 0 | 60 | 90 | 120 | 151 | 180 | 210 |

| 40 para | 1823 | 1823 | 1485 | 1134 | 911 | 770 | 664 |

| 60 para | 1649 | 1649 | 1649 | 1649 | 1367 | 1155 | 995 |

| 80 para | 1907 | 1907 | 1907 | 1907 | 1823 | 1540 | 1327 |

Enhancement Features

High functionality and improve productivity

- Supports different types of ICs (DRAM, LPDDR and NAND) to run in automation test

- Maximum support of 80 pieces of ICs (from 40 DUTs to 80 DUTs) in parallel tests with multiple rubber sockets

- Supports temperatures ranging from ambient temperature to high temperature (up to 85˚C, optional up to 125˚C)

- Supports Empty Socket Checks to prevent damages (such as crushed IC in socket due to unforeseen circumstances)

- Minimizes potential and unexpected problems, increasing productivity

- Supports any customer-selected tester

Specifications

| Item | Description | |

| Device | LPDDR4, DDR4, NAND Min. Ball Pitch ≤ 0.5mm / JEDEC tray |

|

| UPH | Refer to "Reference Cycle-Time" | |

| Jam Rate | 1/20000 | |

| Accuracy (Pick & Place) | ㎛; ≤100㎛ | |

| Load/ Unload Picker | 40 Para: 4 pickers; 60 Para: 6 pickers, 80 Para: 8 pickers | |

| Number of Parallels | 40 Para/ 60 Para/ 80 Para | |

| Stack Tray | 30 trays/ Auto-Bin (4 auto trays) 1 tray/ Manual Bin (2 manual trays) |

|

| Temperature Accuracy | Room temperature ~ +85°C +85°C ± 2°C, Rising time 20 minutes Optional up to ~ +125°C +125°C ± 3°C, Rising time 30 minutes |

|

| Sorting Bin | Auto 4 bins + Manual 2 bins | |

| Socket | 4x10/ 6x10/ 8x10 (Rubber socket) | |

| Ionizer | Stacker (Auto, Manual), Shuttle; 1000V -> 100V : 10 seconds | |

| Dimensions/ Weight | 1900 (W) x 1700 (D) x 1800 (H) mm / approx. 1500 kg | |

| Power | AC 220V ±10% / 3 Phase x 2 (AC power requirements) | |

| Safety | Door Open, System Stop & Motor Free Door Close, Hit START button to restart |

|

| Interface | PC Base: TCP/IP | |

| Interface Protocol | TCP/IP | |

| Optional | Description | |

| Software | Check Socket Empty (Offers free upgrade if needed) Auto Socket Off (Offers free upgrade if needed) |

|

| C.O.K | 4 Units: - Pusher (contractor) Unit - Shuttle Buffer - Pitch Plate - Buffer |

|

Software Screenshot

The GCOM-6040 Software GUI allows user to build tasks via the drag-and-drop interface.

TURBOCATS, LTD. RESERVES THE RIGHT TO CHANGE PRODUCTS, INFORMATION AND SPECIFICATIONS WITHOUT NOTICE. Products and specifications discussed herein are for reference purposes only. All information discussed herein is provided on an "AS IS" basis, without warranties of any kind.