SMH-2P-12D Module Handler

High-quality pick and place module handler

Automated Module Handler for Mass Production

Improved productivity in high-volume manufacturing

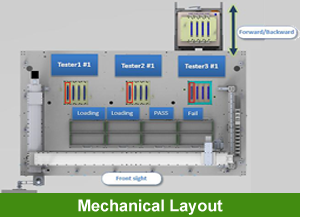

The SMH-2P-12D is a semi-automated Pick and Place module handling system which is fully integrated with the TurboCATS module tester and intuitive software GUI. The handler enables operator-free processing after loading/ unloading and testing.

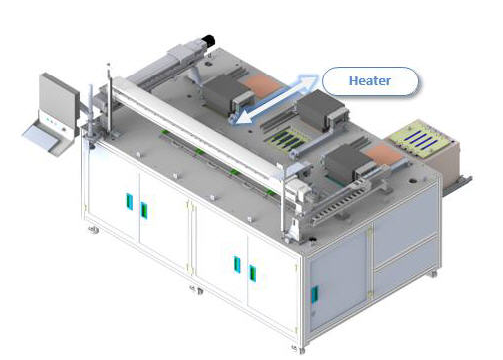

The heat chamber is equipped for high-capacity testing enviroments to minimize potential issues.

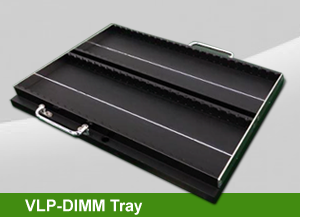

Module Tray Placement

Supports various pin counts (288, 262, 260, 240) and IC density (x4, x8, x16)

Easy operation and easy maintenance

Hot-Temperature Chamber

Precise temperature control

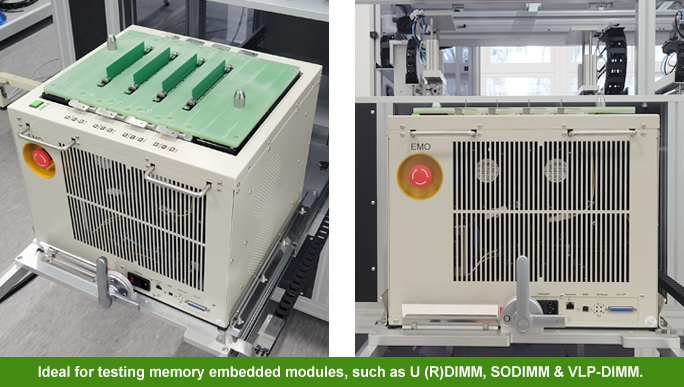

Tester Docking

Equipped with TurboCATS testers to achieve high precise testing standard

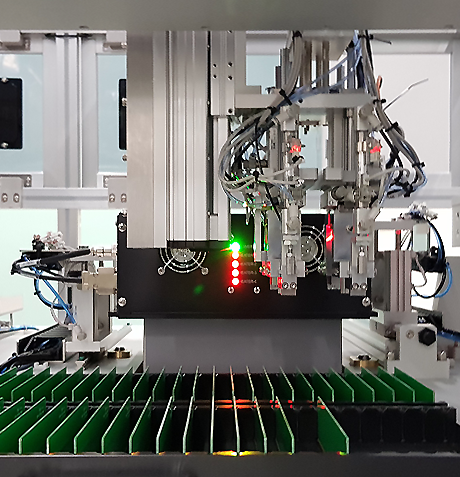

Picker

Dual set of Grippers for transfer and sorting memory modules efficiently

Enhanced Features

Designed for ease of operation

- Designed for different types of DIMM modules: Register/ Unbuffered DIMM, SODIMM, VLP-DIMM, etc

- Supports various Pin Counts (288/ 262/ 260/ 240) and IC/ density (x4, x8, x16)

- Integrated with the TurboCATS module tester to increase the testing capacities

- Heat Chamber: Temperature ranges from 25 to 100°C, tolerance : +/- 3°C, rising time around 8 minute

- Automatic Pick & Place handling system is easy to use for high throughput mass production

- Dual set of Grippers for transfer and sorting standard DIMM memory module efficiently

- Offers precision Pass/ Fail Sorting and eliminate operator errors

Specifications

| Item | Description | Specs | ||

| Product Model | Memory Module | Registered (R), Unbuffered (U), SODIMM, LRDIMM & VLP-DIMM | ||

| Carrier | Module Tray | 2R x 25 pieces ( UDIMM, RDIMM, VLP-DIMM ); 3R x 25 pieces ( SODIMM ) | ||

| Manual Tray | Number of Trays | 4 each ( 2 Loads, 1 Good, 1 Fail ) ** Manual build trays |

||

| Robot | Pick & Place | X, Y, Z-Axis | ||

| Number of Picker | Gripper | 2 Pickers: Shared pickers | ||

| Operation Time | Heat Chamber Operation | Index Time: 66 sec ( First loading ) Cycle Time: 144 sec ( Unload + Sort + Load ) [ Designed Specs ] 1. Test Time = 0 sec 2. BIN Sort = All pass only 3. Minimum test time = 99 sec |

||

| Heat Chamber | Hot Temperature Operation | Temperature Range: 25 ~ 100°C Tolerance +/-3°C Rising time around 8 min |

||

| Standby Temperature → 100°C: 1 min | ||||

| Jam Rate | 1/5,000 | |||

| Dimensions (WxDxH) | Handler Dimensions | 2440 mm x 1530 mm x 1765 mm | ||

| Utility | Power | 220V (Single phase), 8.8KW, 40A | ||

| Air Pressure | 0.5MPa, 12Φ-1 Line | |||

| Interface Protocol | Tester to Handler | TCP/IP | ||

| Handler Control | Controller | Control PC | ||

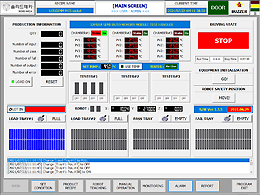

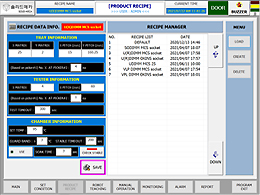

Software Screenshots

Main Operating Screen

Lot Count Report

Binning Report

Recipe Manager

TURBOCATS, LTD. RESERVES THE RIGHT TO CHANGE PRODUCTS, INFORMATION AND SPECIFICATIONS WITHOUT NOTICE. Products and specifications discussed herein are for reference purposes only. All information discussed herein is provided on an "AS IS" basis, without warranties of any kind.