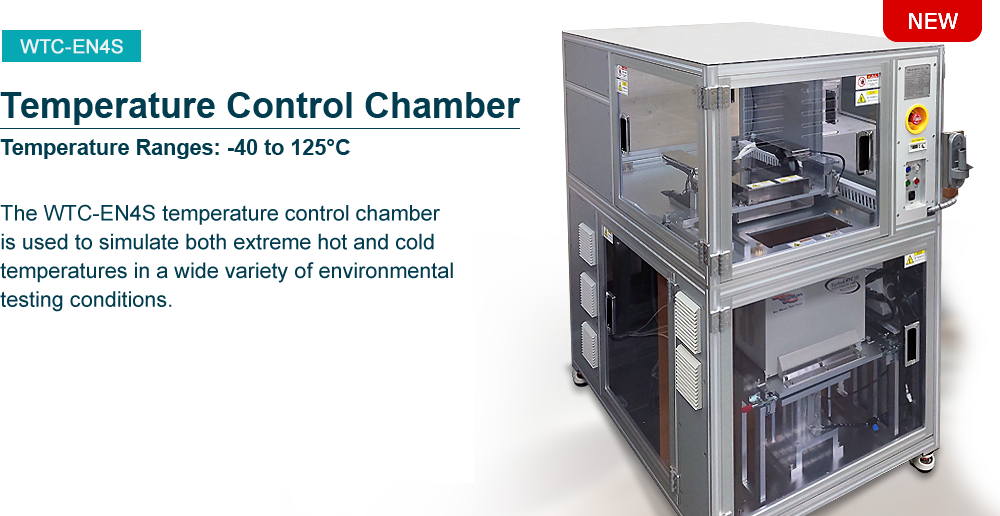

NEW! WTC-EN4S

Temperature Control Chamber

Rapid & Wide Temperature Control Chamber

Designed to provide scalability, flexibility, accuracy and performance

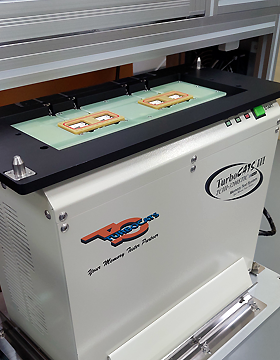

The WTC-EN4S temperature control chamber is equipped with the TurboCATS memory IC tester.

The control chamber integrates rapid and wide temperature directly with the test application. The

wide temperature control chamber is used to test the performance of ICs in various environments.

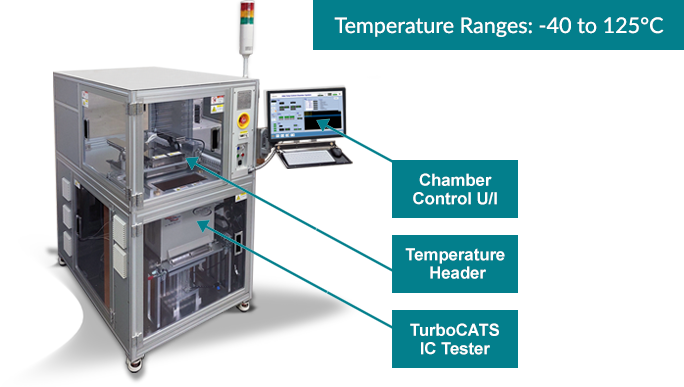

WTC-EN4S Layout

Taking Control of your Testing

Operation Flow

| Step | By | Operation | Remarks | |||

| 0 | Chamber | Initial Stand-by status | Chamber Temp. Control & Tester On-Line is Ready | |||

| 1 | Operator | Loading IC by hands | Manually | |||

| 2 | Operator | Press Start button on the chamber PC UI | Manually | |||

| 3 | Chamber | Temp. Header moves to Front & Down | Alarm/ Popup if Temp. Header has not down surely | |||

| 4 | Chamber | Temp. is rising or falling to Target Temp. | Alarm/ Popup if Temp. Header has not Up/ Down within setting time | |||

| 5 | Chamber PC | Test starts CMD or Tester PC | Send TCP Text Protocol CMD (@STARTTEST+) | |||

| 6 | Tester PC | Test starts receiving CMD to Chamber PC | Reply TCP Text Protocol CMD (@STARTOK+) after got CMD | |||

| 7 | Tester PC | Test ends CMD to Chamber PC | Send TCP Text Protocol CMD (@ENDTEST+) | |||

| 8 | Chamber PC | Test ends receiving CMD to Tester PC | Reply TCP Text Protocol CMD (@ENDOK+) after got CMD | |||

| 9 | Chamber | Temp. Header up for defrost or down cooling | Must keep Defrost Flow when finish Cold Temp. running | |||

| 10 | Chamber | Temp. Header Up & Move to Rear | ||||

| 11 | Operator | Unloading IC by hands | Manually | |||

tR/tF Performance

| Auto Run Recipe | tR/tF Performance | Remarks | ||

| Cold Temp. | 25°C -> 40°C (7 mins) -> Testing -> Defrost (10 mins) -> 30°C (2 mins) |

Defrost flow (-30 Start, 60 End, 30 Step) |

||

| Hot Temp. | 25°C -> 125°C (5 mins) -> Testing -> 30°C (5 mins) | |||

| Cycle Temp. | 25°C -> 40°C (7 mins) -> Testing -> 125°C (7mins) -> Testing -> 30°C (5 mins) |

Example of 2-corner testing | ||

Features

Performance Highlights

Temperature Ranges:

- -40 to 125°C

- Setting Resolution 0.1°C

- Tolerance ±3°C

Rapid Temperature Rising/ Falling Time

- (-40 to 125°C) within 10 minutes

Long Continuity Running Time & Short Defrosting Time Ability

Auto Run Recipe

- Cold, Hot and cycle modes

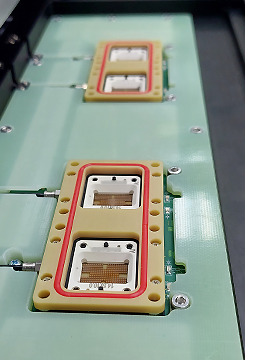

Equipped with TurboCATS IC tester

- DDR/ LPDDR/ NAND ICs

- Supports 4 or 6 DUTs simultaneous testing

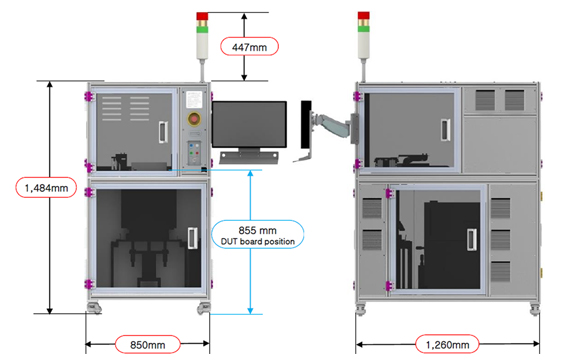

Specifications

| Item | Description | Specifications | Remarks | |||

| Aplication | IC Testing | DDR/ LPDDR/ NAND | 0.5mm~1.3mm IC Thickness | |||

| C.O.K | Temp. Header Set | Based on DUT board | Fixed Temp. Header Set | |||

| PKG Guide | Based on IC dimensions | 200B: 10.0x15.0, 10.0x14.5 | ||||

| Hot/ Cold Chamber | Temp. Range | ~40 ~ 125C° | Temperature Control: At the end of the contact pusher | |||

| Setting Temp. Resolution | 0.1°C | |||||

| Temp. Tolerance | ±3°C | |||||

| Temp. Rising Time | 5 mins (-40 -> 25°C) | Spec. tR/tF time is based on the real performance with the guard band | ||||

| 5 mins (25 -> 125°C) | ||||||

| 7 mins (-40 -> 125°C) | ||||||

| Temp. Failing time | 5 mins (125 -> 25°C) | |||||

| 7 mins (25 -> 40°C) | ||||||

| 10 mins (125 -> 40°C) | ||||||

| Running Time | < 30 hrs (at Cold Temp.) | System Continuity | ||||

| < 60hrs (at Hot Temp.) | ||||||

| Defrosting Time | 10 mins (-30 -> 60 -> 30°C) | Only after Cold Temp. | ||||

| Utility | Power for Chamber | 200V (Single phase) 16A | ||||

| Power for Chiller | 220V (Single phase) 16A | |||||

| Compressed Air | 0.5MPa 8ø 1 Line | Prevents dew condensation | ||||

| Interface Protocol | Chamber to Tester | TCP/IP | TCP Text Protocol | |||

| Chamber Control | Control PC | Industrial PC | ||||

| Control Cylinder | PLC | |||||

| Dimensions | (Width x Depth x Height) | 850 x 1260 x 1484 mm | Excluded Tower Lamp (447mm) | |||

| Weight | Net Weight | Approx. 325 kg | ||||

Note: Information and data are for reference only. Contact our sales team for more details.

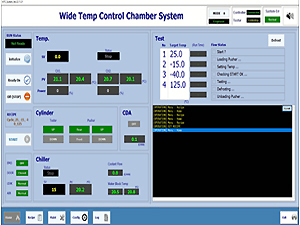

Software Screenshot

Chamber Control U/I

TURBOCATS, LTD. RESERVES THE RIGHT TO CHANGE PRODUCTS, INFORMATION AND SPECIFICATIONS WITHOUT NOTICE. Products and specifications discussed herein are for reference purposes only. All information discussed herein is provided on an "AS IS" basis, without warranties of any kind.