Reliable TCIII-3600ST DDR5 & DDR4 Module Tester

Designed for ease of operation

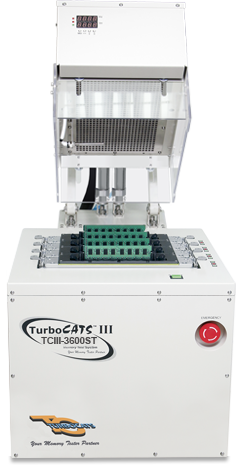

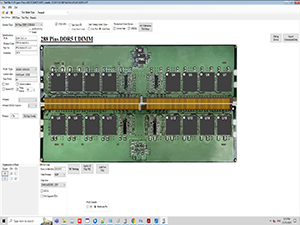

The DDR5 technology is quickly progressing and tests multiple modules that is critical to cost-effective memory. TurboCATS introduces a new line of redesigned TCIII-3600ST DDR5 and DDR4 multi-site module testing system - compact, high-performance, and equiped with enhanced productivity features. The TurboCATS TCIII-3600ST module tester features an optional 4 (standard), 8, or 16 module testing, in parallel, for high throughput on your production floor.

One of the most difficult challenges faced by memory manufacturers is finding a cost effective method to test their products so they can minimize time to market and field failures/ returns. The manpower and equipment required for the extensive testing often result in budget overruns for various cost centers.

High-end ATE's are designed to detect functional and AC/ DC parametric failures but can not identify or pinpoint potential in-system failures. Most in-system failures are caused by functional and timing compatibility issues that are generated by the system chipset. Many in-system device failures occur during system boot up or during performance of a specific operation within a given system. To effectively deal with functional testing to include AC and DC parametric testing, most memory manufacturers incorporate a costly testing process as part of their Standard Operating Procedure (S.O.P.).

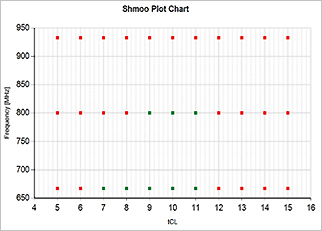

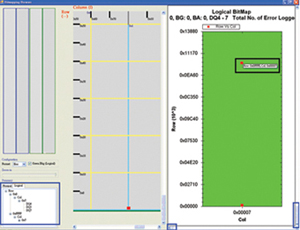

Device characterization and failure analysis tools, such as Shmoo plotting and address/ data error logging are included in the TCIII-3600ST to assist engineers with their design/ debug processes.

An optional hot temperature chamber is available to detect marginal timing and cell storage failures that often occur in high temperature system environments. The chamber is user programmable and can be set at temperatures ranging from 32°C to 85°C.

Fully Configurable Features

DDR5: 3200Mbps, 3400Mbps, 3600Mbps DDR4: 1600Mbps, 1866Mbps, 2133Mbps, 2667Mbps, 2866Mbps, 2933Mbps, 3200Mbps DDR5 PMIC (Power Management IC) test - Clock Frequency from 800MHz to 1800MHz

- Supports form factors - LODIMM, SODIMM, LRDIMM and custom form factors

- Over 35 standard industry test patterns

- Configurable to 4 (standard), 8 or 16 sites in parallel testing

- Manual/ Semi-automatic handler testing

DDR5 PMIC (Power Management IC) Testing

FEATURES

DDR5 UDIMM PMIC

- Bulk Input Supply Voltage: 4.25 to 5.5V (4A)

DDR5 RDIMM/ LRDIMM PMIC

- Bulk Input Supply Voltage: 4.25V to 15V (4A)

- Management Input Supply Voltage: 3V to 3.6V (1A)

PMIC Testing

- Power Short Test

- Open/ Short Test

- Read ID

- Register Test

- Program/ Secure Mode Test

- VR_EN Test (Power Up/ Down Sequence Test)

- PG/ Error Injection Test

- Over Clock Chip Test

- Read/ Program DIMM Vendor Register

- VIN_Bulk switchover function (RDIMM only)

- VIN_Bulk transition function (RDIMM only)

- Input/ Output Voltage Monitor

- Output Current/ Power Monitor

- SPD Hub/ PMIC Temperature Monitor

Power Integration Tools

Combination of Failures

- Functional Failure: Cell stuck-at, coupling, neighborhood sensitivity and software error faults

- Parametric Failure: Speed timing vs. Vdd threshold, (DC) Leakage and Idd's

- Hot-Temperature Failure: System high temperature environment

Multi-Site Networking

Don't let old technology keep you from getting ahead

TurboCATS is innovating with the new TCIII-3600ST DDR5/ DDR4 multi-site test system that will test 4 modules in parallel. Testers are available in 4 , 8 or 16 sites configuration, in parallel testing.

TurboCATS can meet all of your testing needs while keeping costs at a minimum. Costs are minimized since there will be no need for additional manual labor to handle the increased capacity. The user can simply integrate the new unit into their existing network and utilize the PC that is already in place.

Network-Interface Features

- Network-ready and High-performance

- Ideal for powered productivity

- Graphical user interface software

- Real-time configuration and monitoring

- Advanced reporting

- Remote file editing

- Firmware upgrade via internet

Handler Interface

Supports Semi-Automated Module Handler

The TCIII-3600ST DDR5 and DDR4 module system can be configured to 4, 8 or 16 sites and integrated with the handler interface to support the SMH-2P-12D Semi-automated Handler testing.

Handler Interface Features

- Designed for different types of DIMM modules: Register/ Unregistered DIMM, SODIMM, VLP-DIMM, etc

- Supports various Pin Counts (288/ 260/ 240) and IC/ density (x4, x8, x16)

- Integrated with the TurboCATS module system to increase the testing capacities

- Automatic Pick & Place handling system is easy to use for high throughput mass production

- Offer precision Pass/ Fail Sorting and eliminate operator errors

Features

Everything in one place

Test Capabilities

DDR5 - 3200Mbps, 3400Mbps, 3600Mbps DDR4 - 1600Mbps, 1866Mbps, 2133Mbps, 2667Mbps, 2866Mbps, 2933Mbps, 3200Mbps - Clock frequency from 800MHz to 1800MHz

AC/ DC Parametric and Function Tests

- Supports AC/ DC Parametric and User Script Pattern Programming

- Over 35 standard industry test patterns

- DDR5/ PMIC (Power Management IC) Test

- Power/ Pins short, contact, leakage, connectivity and Idd's testing

- Enhanced DC function VSIM

- Supports SPD Programming, Read/ Write test, Write-Protect, etc.

- Auto-Timing Calibration

- Optionally Supports 12V pin of DDR4 for changing backup energy storage devices

Powerful Failure Analysis Tools

- Graphical interface displays Failed IC's and Failed DQ's

- Error logging of Row/ Column/ Blanks/ Burst/ DQs

- Supports Address Scramble/ Data Scramble

- Useful tools including Bit Failure Mapping and Shmoo Plot

Flexible Configuration

- Supports form factors: LODIMM, SODIMM, RDIMM, LRDIMM and custom form factors

- Standard 4-site module testing, in parallel for a high throughput on production floor

- Single adapter supports both unbuffered and registered module testing

- Optional:

- - 8 or 16 module testing, in parallel, for high throughput on production floor

- - Heat chamber for hot environmental testing from 32°C to 85°C

- - Handler interface for combining the TCIII-3600ST with a semi-automated handling system

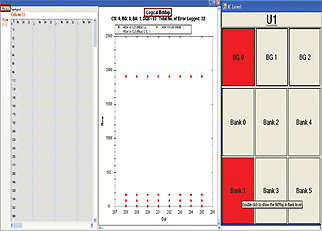

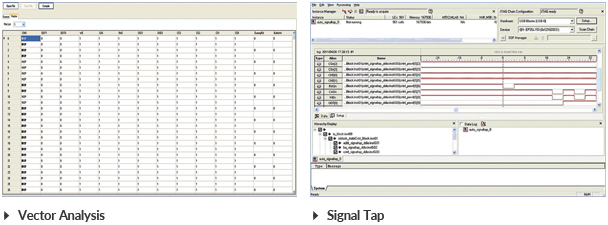

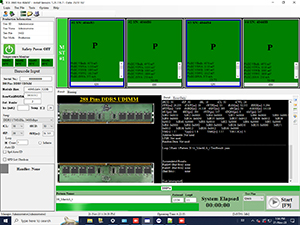

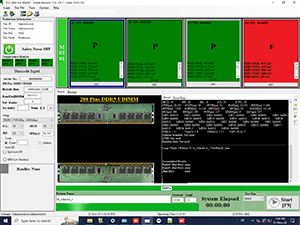

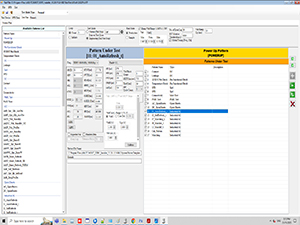

GUI Failure Analysis Tool

Graphical Identification of DQ's

At the end of the test, the appropriate color will indicate the failed ICs (red) on the module. The indicated color reset automatically at the start of each test. The software uses a graphical picture to illustrate the test failures at the hardware level.

- All failed ICs on the module

- Corresponding failed IC pins in red

Shmoo Plot

A two-dimensional diagram that shows the status of the DQ bits of Memory ICs varying over a range of the users' selected parameters (timing and input voltage levels).

Bit Failure Mapping

A tool that helps users find and display the failed DQ bits in the RAM. The corresponding row and column address the failed DQ bits, which will be spotted and dsiplayed for the users.

Script Code Function

Script Code Debugger

Traditional test systems provide the user with a variety of AC test patterns to use in their testing process. If a user wanted the capability to generate a proprietary test pattern, then they have to purchase a high-end automated test system. For most companies this is cost prohibitive and not a viable option.

TurboCATS designed a new feature called the Script Code in the new DDR5 and DDR4, the TCIII-3600ST memory test system. In the new system, the user can use the script programming language to create a customized test pattern.

The Script Code function serves as a powerful compiler/ debug tool. It contains a built-in compiler and debugger for the Script Code programming which allows the user to monitor the timing waveform of the programming algorithm as well as the timing bus transactions. This is all accomplished under the Signal Tap tool.

DC Checking Function

Contact, Leakage, Connectivity and 12V Pin

| Item | Description |

|---|---|

| Contact | This will detect any open pins on the contacts between test sockets & ICs before the functional testing begins. It will also detect any open pins on both passive and memory components on the PCB. |

| Leakage | This will detect the leakage current (in and out) of the IC pins. |

| Connectivity | This will detect shorts on the signal line as well as the proper values of resistor packs and discrete resistors to ensure that their values are proper and the ICs are properly mounted. |

| 12V Pin (optional) | This will detect shorts on 12V power pin of DDR4 (NVDIMM) during the Initial Test. |

Specifications

| DDR5 Clock Frequencies | 1600MHz to 1800MHz | |

| DDR5 Data Rate | 3200Mbps, 3400Mbps, 3600Mbps | |

| DDR4 Clock Frequencies | 800MHz to 1600MHz | |

| DDR4 Data Rate | 1600Mbps, 1866Mbps, 2133Mbps, 2667Mbps, 2866Mbps, 2933Mbps, 3200Mbps | |

| DDR5 Vdd | 1.06V to 1.17V | |

| DDR4 Vdd | 1.14V to 1.30V | |

| Data Width | 72 bits in parallel | |

| Address Depth | DDR5 - 18 Rows, 15 Columns, 5 BAs DDR4 - 18 Rows, 15 Columns, 4 BAs |

|

| Programmable Timing Cycles | tRCD, tAL, tCL, tWL, tRL, tWR, tRRP, tRP, tRFC, etc. | |

| Burst Length | DDR5 - 16 BL DDR4 - 8 BL |

|

| ODT Selection | ||

| OCD Adjustment | Auto calibration | |

| All Standard Idd's current test | ||

Heat Chamber

Integrating the TCIII-3600ST with Heat Chamber

The heat chamber creates a high temperature testing environment to simulate the accelerated life testing and analyze the behaviors of the module.

To assist manufacturers and integrators, TurboCATS has developed a heat chamber that can be integrated with the TCIII-3600ST DDR5 and DDR4 multi-site test system. This allows the module and its components to be tested while being exposed to heat conditions similar to what they might encounter in a PC or a laptop.

Heat Chamber Specifications

| Power Supply | 220V, 50Hz (90 - 110% of rated voltage) |

| Power Consumption | Power-up: 15A, 220V |

| Normal operation: 10A, 220V | |

| Display Method | 7 Segment LED Display |

| Processing Value (PV): Green | |

| Setting Value (SV): Red | |

| Temperature Range | 25°C - 85°C |

| Recommended Setting Temperature | 80°C |

| Air Input | Min. 0.5 MPa - Max. 1.0 MPa |

| Min. 75 psi - 145 psi | |

| Diameter of Gas Tube | 6 mm |

Software Screenshots

Main Operating Window - Passed

Main Operating Window -Failed

Test Plan

Test Device

TURBOCATS, LTD. RESERVES THE RIGHT TO CHANGE PRODUCTS, INFORMATION AND SPECIFICATIONS WITHOUT NOTICE. Products and specifications discussed herein are for reference purposes only. All information discussed herein is provided on an "AS IS" basis, without warranties of any kind.