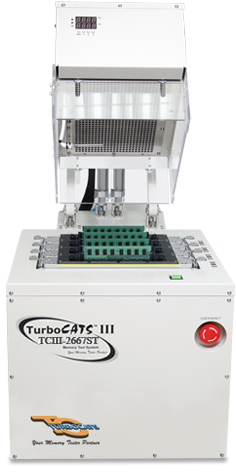

TurboCATS III-2667ST Multi-site Test System

Accelerate your testing with faster performance

TurboCATS proudly introduces the multi-site TCIII-2667ST DDR4 and DDR3 memory test system.

DDR4 - supports speeds up to 2667MbpsDDR3 - supports speeds up to 1866Mbps- Supports form factors - LODIMM, SODIMM, LRDIMM and custom form factors

One of the most difficult challenges faced by memory manufacturers is finding a cost-effective method to test their products so they can minimize time to market and field failures/ returns. The manpower and equipment required for the extensive testing often result in budget overruns for various cost centers.

High-end ATE's are designed to detect functional and AC/ DC parametric failures but do not identify or pinpoint potential in-system failures. Most in-system failures are caused by functional and timing compatibility issues that are generated by the system chipset. Many in-system device failures occur during system boot-up or during performance of a specific operation within a given system. To effectively test to include AC and DC parametric testing, most memory manufacturers incorporate a costly testing process as part of their Standard Operating Procedure (S.O.P.).

An optional hot temperature chamber is available to detect marginal timing and cell storage failures that often occur in high temperature system environments. The chamber is user programmable and can be set at temperatures ranging from 32°C to 85°C.

GUI Failure Analysis Tool

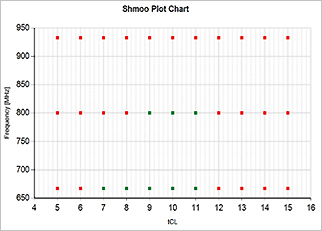

Shmoo Plot

Shmoo Plot is a two-dimensional diagram showing the status of the DQ bit of memory modules varying over a range of the user-selected parameters (timing and input voltage level).

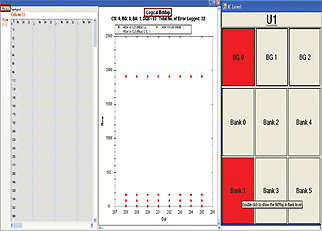

Graphical Identification of Failed DQs' Locations

- All bad ICs on the module

- Corresponding bad IC pins in red

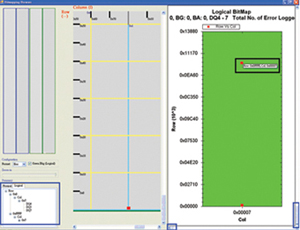

Bit Failure Mapping

This is a tool that helps users to find and display the failed DQ bits in the ICs. The corresponding row and column displays the failed DQ bits with the aid of the diagrams.

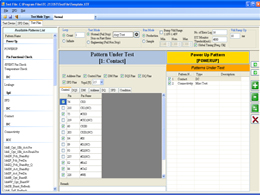

Script Code Function (optional)

Script Code Debugger

TurboCATS designed a new feature called the Script Code programming in the multi-site DDR4 and DDR3 TCIII-2667ST tester. User can use the script programming language to create a customized test pattern. It can support up to a maximum of 2048 data patterns (optional). Once the pattern is created, the Script Code pattern generator/ compiler is used to compile the code and then generate the new test pattern.

Enhanced DC (VSIM)

1. Voltage Sense and Current Measurement (VSIM)

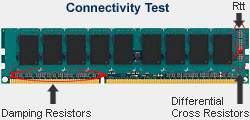

This will detect shorts on the signal line as well as detect proper values of resistor packs and discrete resistors to ensure that their values are proper and the ICs are properly mounted.

A pattern that will detect any open pins on the contacts between test sockets and DIMM's before functional testing begins. This pattern will also detect any open pins on both passive and memory components on the PCB.

2. System Power Short Protection

3. VREFCA/ VREFDQ

Voltage ref short detection including programmable VREFCA and VREFDQ.

Multi-Site Networking

The ideal networking solution for growing businesses

The TCIII-2667ST DDR4/ DDR3 multi-site unit can be networked so the user can test up to 64 modules in parallel using only one PC to control the entire operation. This allows the user greater flexibility in terms of increasing testing capacity on an as-needed basis. The user can add new testers when they need the capacity.

Handler Interface (optional)

Integrated to DDR4/ DDR3 module testing & test up to 64 sites

The TCIII-2667ST memory test system can be configured to 8, 16, or 64 sites and integrated with the handler interface to support automated handler testing.

Features

Test Capabilities

- DDR3 - 1333Mbps, 1600Mbps, 1866Mbps

- DDR4 - 1866Mbps, 2133Mbps, 2400Mbps, 2667Mbps

- Clock frequency from 667MHz to 1334MHz

Powerful Failure Analysis Tool

- Graphical Failure display shows Failed Bad ICs and DQ pins' location

- Error logging location of Row/ Column/ Blanks/ Burst/ DQs for analyzing failures

- Address Scramble/ Data Scramble

- Includes optional tools Bit Failure Mapping and Shmoo Plot to display the failed Bank(s)/ DQ bits in the RAM

AC/ DC Parametric & Function Test

- Supports AC/ DC parametric testing and user script pattern programming

- Over 35 standard industry test patterns

- Power/ Pins short, contact, leakage, connectivity and Idds testing

- Enhanced DC function VSIM to detect any short on the signal line or any open of the component's contact on PCB

- Supports SPD Programming, Read/ Write test, Write-Protect, etc.

- Auto-Timing Calibration

- Supports optional 12V pin of DDR4 for changing backup energy storage devices

Flexible Configuration

- Supported form factors: LODIMM, SODIMM, RDIMM, LRDIMM and custom form factors

- Standard 4-site module testing in parallel is available for a high throughput on production floor

- Single adapter supports both unbuffered and registered module testing

- Optional:

- - 8, 16 or 64 module testing is available

- - Heat chamber for testing in high temperature environment from 32°C to 85°C

- - Handler interface is available for combining the TCIII-2667ST with an automated handler

AC Specifications

| Test Frequency | DDR3 | 533Mhz - 933Mhz |

| DDR4 | 800Mhz - 1334Mhz | |

| Switching Data Rate | DDR3 | 1066Mbps - 1866Mbps |

| DDR4 | 1600Mbps - 2667Mbps | |

| I/O Interface | DDR3 | SSTL-15, Class I & Class II SSTL-135, Class I & Class II |

| DDR4 | POD12 - 1.2V Pseudo Open Drain I/O | |

| Clock Lines | 3 pairs per site | |

| Address Depth | DDR3 | 16 Rows, 15 Columns, 3 Banks 16X/ 15Y/ 3Z per site |

| DDR4 | 18 Rows, 15 Columns, 4 Banks 18X/ 15Y/ 4Z per site |

|

| Data Width & Depth | 72 I/O per site | |

| Data Depth | Supports 8/ 16/ 32 bit IC devices | |

| DQS's | Differential | |

| Control Lines | 4 CS's, 2 CLKE, 1 RAS, 1 CAS, 1 WE, etc. per site, up to 16 sites | |

| Termination | On-chip, dynamic | |

| Variable Timing Edges | tSU/ tHD, tWD, tDQSS, tAC, etc. | |

| Programmable Timing | tRCD, tRP, tCL, tAL, tCWL, tWR, tRL, tWL, tRFC, etc. 1 pair of clock per IC socket |

|

| SPD Program | Read, Program, Edit, Test, Byte Matching, Serialization, Write-Protect, Slot Test, etc. |

|

| Control PC Requirements | Windows 7 or above, Networking interface | |

| AC Power Source | 110-240VAC, 50/60Hz | |

TCIII-2667ST Family with Heat Chamber (optional)

To enhance the reliability of the modules

The heat Chamber creates a high temperature testing environment to simulate the accelerated life testing and analyze the behaviors of the module.

To assist manufacturers, and integrators, TurboCATS has developed a heat chamber that can be integrated with the TCIII-2133ST DDR4/ DDR3 tester. This allows the module and its components to be tested while being exposed to heat conditions similar to what they might encounter in a PC or a laptop.

Heat Chamber Specifications

| Power Supply | 220V, 50Hz (90 - 110% of rated voltage) |

| Power Consumption | Power-up: 15A, 220V |

| Normal operation: 10A, 220V | |

| Display Method | Red 7 Segment LED Display |

| Storage Temperature | -20°C - 60°C |

| Ambient Humidity | 35% - 85% RH |

| Temperature Range | 25°C - 85°C |

| Recommended Setting Temperature | 80°C |

| Air Input | Min. 0.5 MPa - Max. 1.0 MPa |

| Min. 75 psi - 145 psi | |

| Diameter of Gas Tube | 6 mm |

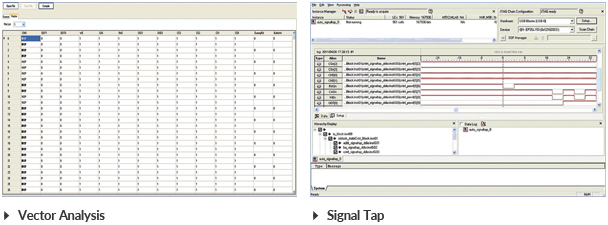

Software Screenshots

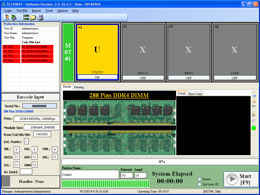

Main Operating Window

Test Device Configuration

Test Plan

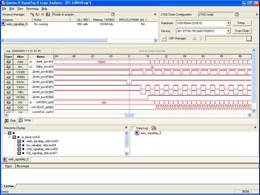

Signal Tap

TURBOCATS, LTD. RESERVES THE RIGHT TO CHANGE PRODUCTS, INFORMATION AND SPECIFICATIONS WITHOUT NOTICE. Products and specifications discussed herein are for reference purposes only. All information discussed herein is provided on an "AS IS" basis, without warranties of any kind.